1. Simple structure and low operating cost;

2. High crushing ratio with low consumption;

3. Function of fine crushing and crude grinding;

4. Slightly influenced by moisture content of material, and the max moisture content is about 8%;

5. More suitable for crushing mid-hardness and high hardness materials;

6. Cubic shape of final products, high density of piling up and low iron pollution;

7. More wearable and easier maintenance;

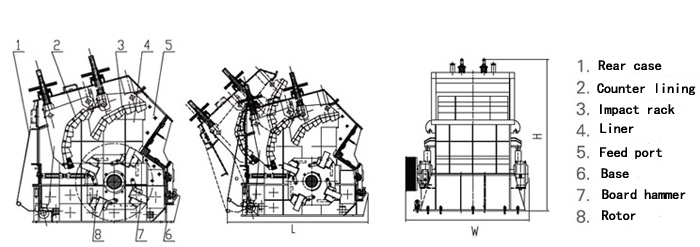

Impact crusher is generally used as secondary crusher, and by changing rotor and crushing cavity, it can also be used as primary crusher according to the customer’s requirements. It is widely used in highway, reservoir, railway, airport and other fields that need rock with cubic shape. It features high capacity, high performance, high reduction ratio, cubic shape and low flakiness.

Technical Paremeters:

| Model | Spec of Rotor (mm) | Feed Opening Size (mm ) | Max. Feed Edge (mm) | Processing Capacity (t/h) | Motor Power (kw) | Weight (t) | Overall Dimensions (L×W×H) (mm) |

| PF-1007 | φ1000×700 | 400×730 | 300 | 35-50 | 30-55 | 9.45 | 2400×1558×2660 |

| PF-1010 | φ1000×1050 | 400×1080 | 350 | 50-80 | 55-75 | 12.2 | 2400×2250×2660 |

| PF-1210 | φ1250×1050 | 400×1080 | 350 | 80-120 | 110-132 | 14.4 | 2690×2338×2890 |

| PF-1214 | φ1250×1400 | 400×1430 | 350 | 130-180 | 132-160 | 16.85 | 2690×2688×2890 |

| PF-1316 | φ1300×1600 | 858×1640 | 350 | 150-220 | 200 | 19.5 | 3096×3273×2667 |

| PF-1010V | φ1000×1050 | 400×1080 | 350 | 55-85 | 55-75 | 13.2 | 2400×2250×2660 |

| PF-1210V | φ1250×1050 | 400×1080 | 350 | 70-120 | 110-132 | 15.1 | 2696×2338×2890 |

| PF-1214V | φ1250×1400 | 400×1430 | 350 | 99-160 | 132-160 | 17.85 | 2690×2688×2890 |

| PF-1310V | φ1300×1050 | 490×1170 | 350 | 70-120 | 110-160 | 13.5 | 2780×2478×2855 |

| PF-1315V | φ1320×1500 | 860×1520 | 350 | 150-220 | 180-220 | 20.75 | 3007×2749×2556 |

| PF-1515V | φ1500×1500 | 850×1580 | 350 | 220-280 | 280-315 | 28.5 | 3553×2835×3277 |

| PF-1620 V | φ1640×2000 | 800×2020 | 400 | 400~550 | 250×2 | 39 | 3505×3740×3085 |